The Slash 2 Plus is one of the company’s highest-performance 3D printers to date, with a focus on speed and productivity to address the high-volume needs of the professional dental market. Specifically targeting dental applications, the company has even developed a set of FDA-approved dental materials, including the zDENTAL IDB for indirect bonding trays and the zSG Amber for surgical guides and brackets.

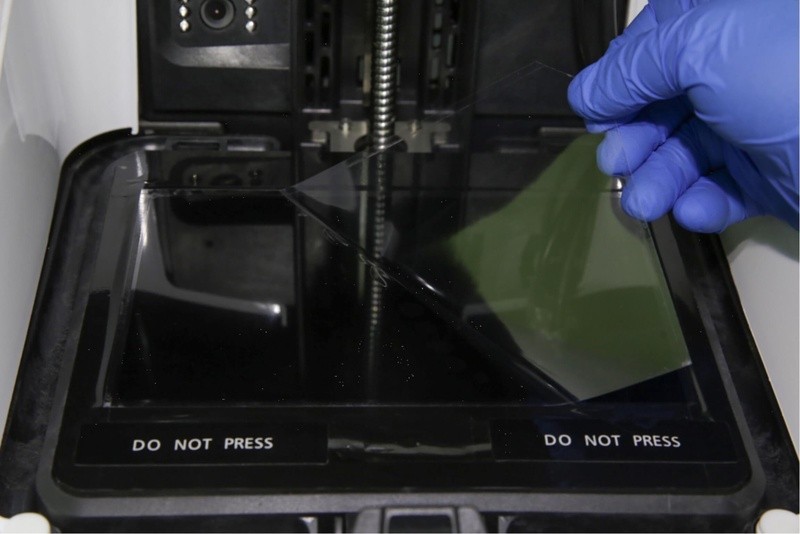

UNIZ also has more than 40 patents to its name, which cover both the high-speed printing technology and the firm’s own range of resins. Photo via UNIZ.īased in San Diego, UNIZ has slowly crafted a name for itself in the resin 3D printing space, now offering an entire portfolio of LCD 3D printers for the professional market. The UNIZ SLASH 2 PLUS is designed for high-speed dental 3D printing. The machine also comes complete with the firm’s new UNIZ Dental slicing software, a high-speed print preparation program designed for high-throughput dental printing. With the goal of combining speed and precision to streamline digital dentistry, the Slash 2 Plus is primarily aimed at dental professionals and labs for applications such as custom aligner models, model trays, surgical guides, crowns, bridges, night guards, and more. The professional-grade LCD machine is based on the company’s original Slash 2 3D printer, and sports an 8.9” 4K Mono LCD screen, UNIZ’s patented LED light engine, and a second-generation liquid cooling system. Blending with mixed fillers is the most common method of producing the nanofiber composite.UNIZ, a manufacturer of desktop 3D printers, has begun shipping its new resin-based Slash 2 Plus system. Polymer matrix nanofiber composite can be routinely produced using Electrospinning with electrospinnable polymers usually produce. Finaly, a post spinning sintering process converts then the precursor nanofibers into the metal oxide nanofibers. For example, the precussor to produce titanium dioxide, is often titanium isopropoxide. Metal oxides: Many metal oxides have important industrial applications due to their catalytic properties and photoactivity. For commercially important polymers such as polyethylene and polypropylene which dissolves in few solvents, melt electrospinning provides an alternative option.Ĭarbon: Since most polymers are made from a carbon backbone, carbon nanofibers can be made with post electrospinning carbonization process. Generally, these polymers should have a high molecular weight and can be dissolved in a solvent.

Tumaker Pro Dual Direct Drive HR – PelletsĪ broad range of polymers have been electrospun which covers industrial polymers, biodegradable polymers, speciality polymers and natural polymers.Tumaker Pro Dual Direct Drive HR – Direct Drive HR.

0 kommentar(er)

0 kommentar(er)